| Pico Energy Ltd | Case Study 6 | Site Name: | Algars Mill |

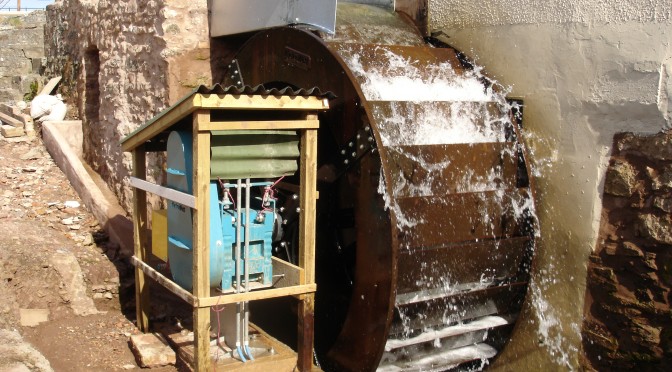

| System type: | Francis Turbine (installed 1924) |

Power output: | 1.5 kW (single phase) |

| Manufacturer: | Gilkes | Typical Generation: | 5 MWh p.a. |

| Client: | Mr and Mrs Wright | Design Conditions: | H = 1.70 m Q = 0.15 m3/s |

| Location: | Iron Acton, Bristol | Commissioned: | October 2009 |

Project description:

This former watermill was originally attached to the neighbouring manor house and originally adapted for electricity production to supply the house in 1924. The DC alternator had long since disappeared and well before the current owners who have lived there for the last 27 years. A resource assessment and appraisal of the remaining open flume turbine was carried out.

The most cost-effective hydropower option identified was to refurbish the existing turbine and install a new induction generator and control system. An actuation mechanism was also designed to allow the system to start and stop automatically and respond to varying flow rates. Refurbishment required complete removal of the turbine, replacement of the guide vane linkages, drive shaft and bearings, blasting and repainting. A G83 grid connection system was installed so that the modest amounts of power generated could be directly used by the household loads. The scheme is registered for the Feed in Tariff.