| Hydromatch Consulting | Case Study 4 | Site Name: | Currypool Mill |

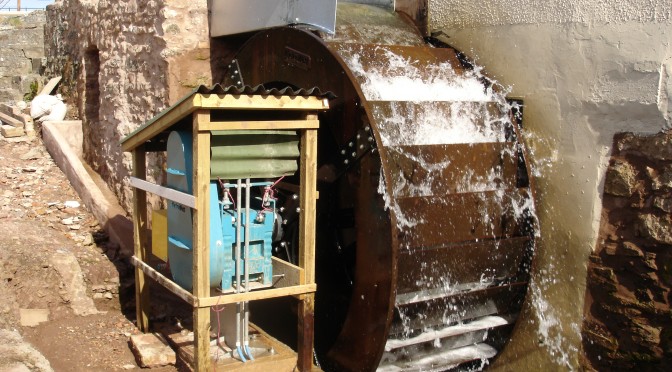

| System type: | Overshot Waterwheel | Power output: | 6.5 kW 3 phase |

| Manufacturer: | HydroWatt GmbH | Typical Generation: | 30 MWh p.a. |

| Client: | Mr and Mrs Taylor | Design Conditions: | H = 3.20 m Q = 0.35 m3/s |

| Location: | Cannington, Somerset | Commissioned: | November 2006 |

Project description:

A sawmill in a previous life, Currypool Mill was renovated by its new owners and converted into a family home. Options for power generation including a crossflow turbine and an overshot waterwheel were compared in terms of cost, power output and suitability for integration with the surrounding buildings. The simplicity, overall efficiency and lack of screening required favoured reinstatement of a waterwheel.

An old badly broken ‘Armfield’ turbine was removed and a new launder was installed along with an overshot wheel made from Corten steel, which was carefully dimensioned to fit the existing wheel pit.

The system operates without active flow regulation under normal generating conditions. During shutdown the flow is diverted behind the wheel via a trap door sluice in the launder. If the power is interrupted, the hydraulic circuit which normally holds the sluice shut, is de-energised and the door opens under its own weight. This provides a failsafe means of controlling the system.

The power produced is exported to the grid on a net metering basis. This enables the power to be consumed in the building if sufficient demand exists or otherwise exported. The system has been registered with OFGEM for the awarding of ROCs since 2006.